Yeej, cov txheej txheem cov tshuaj tiv thaiv ntawm tag nrho cov carbohydrates synthesized los ntawm Fischer nrog alkyl glycosides yuav txo tau mus rau ob txheej txheem variants, namely, ncaj synthesis thiab transacetalization. Nyob rau hauv ob qho tib si, cov tshuaj tiv thaiv tuaj yeem tshwm sim hauv batch lossis tsis tu ncua.

Raws li kev sib txuas ncaj qha, cov carbohydrate reacts ncaj qha nrog cov roj cawv kom tsim tau cov saw ntev alkyl polyglycoside. Cov carbohydrate siv feem ntau qhuav ua ntej cov tshuaj tiv thaiv tiag tiag (piv txwv li tshem tawm cov dej siv lead ua hauv cov kua nplaum monohydrate = dextrose). Cov kauj ruam ziab no txo qis cov kev cuam tshuam sab nraud uas tshwm sim nyob rau hauv lub xub ntiag ntawm dej.

Hauv kev sib txuas ncaj qha, hom monomer khoom qabzib yog siv los ua cov khoom sib xyaw zoo.Vim tias cov tshuaj tiv thaiv yog cov tshuaj tiv thaiv tsis sib xws / kua, cov khoom yuav tsum raug tshem tawm tag nrho hauv cawv.

Cov piam thaj ntau degraded (DE> 96; DE = Dextrose equivalents) tuaj yeem ua rau muaj kev hloov pauv ncaj qha. Kev siv cov kuab tshuaj thib ob thiab / lossis emulsifiers (piv txwv li alkyl polyglycoside) muab kev ruaj khov zoo-doplet dispersion ntawm cawv thiab piam thaj syrup.

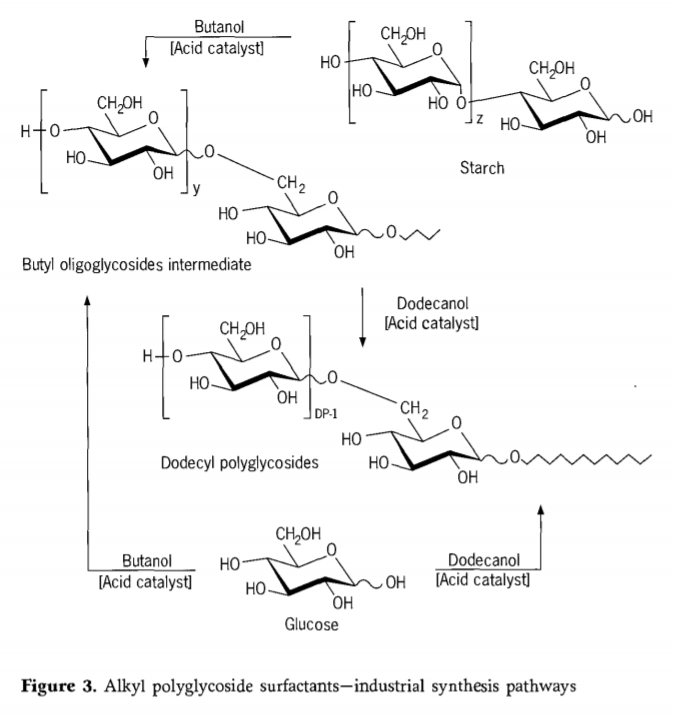

Cov txheej txheem ob-theem transacetalization yuav tsum muaj cov cuab yeej siv ntau dua li kev sib txuas ncaj qha. Nyob rau hauv thawj theem, cov carbohydrate reacts nrog ib tug luv luv-chain cawv (piv txwv li n-butanol los yog propylene glycol) thiab optionally deploy-menzes. Hauv theem thib ob, cov saw luv luv alkyl glycoside yog transacetalized nrog cov kab txuas ntev ntev los tsim cov alkyl polyglycoside xav tau. Yog hais tias tus molar ratio ntawm carbohydrate rau cawv yog tib yam, lub oligomer tis tau txais nyob rau hauv tus txheej txheem ntawm transacetalization yog yeej ib yam li uas tau txais nyob rau hauv lub ncaj synthesis.

Yog tias oligo-thiab polyglycoses (piv txwv li cov hmoov txhuv nplej siab, syrups nrog tus nqi qis DE) raug siv, cov txheej txheem transacetalization yog siv. Qhov tsim nyog depolymerization ntawm cov khoom pib no yuav tsum tau kub ntawm> 140 ℃. Nws yog lub hauv paus ntawm cov cawv siv, qhov no tuaj yeem tsim kev sib raug zoo siab dua uas ua rau muaj kev xav tau ntau dua ntawm cov khoom siv thiab tuaj yeem ua rau cov nqi cog ntau dua. Nyob rau hauv dav dav, ntawm tib lub peev xwm, cov txheej txheem transacetalization raug nqi ntau dua li kev sib txuas ncaj qha. Ntxiv rau ob theem tshuaj tiv thaiv, yuav tsum tau muab cov chaw khaws cia ntxiv, nrog rau kev xaiv chaw ua haujlwm rau cov dej cawv luv luv. Vim hais tias tshwj xeeb impurities nyob rau hauv cov hmoov txhuv nplej siab (xws li cov proteins), alkyl glycosides yuav tsum tau mus ntxiv los yog finer refining. Nyob rau hauv cov txheej txheem transacetalization yooj yim, syrups nrog cov ntsiab lus qabzib siab (DE> 96%) lossis cov khoom qabzib tuaj yeem hnov mob nrog cov dej cawv luv luv nyob rau hauv lub siab, cov txheej txheem txuas ntxiv tau tsim los ntawm lub hauv paus no. (Daim duab 3 qhia ob txoj kev sib txuas rau alkyl polyglycosides)

Post lub sij hawm: Sep-29-2020