Cov qauv tsim ntawm alkyl glycoside ntau lawm cog raws li Fisher synthesis nyob ntawm ntau yam ntawm cov carbohydrate siv thiab cov saw ntev ntawm cov cawv siv.Kev tsim cov dej-soluble alkyl glycosides raws li octanol / decanol thiab dodecanol / tetradecanol yog thawj zaug. Alkyl polyglycosides uas, rau ib tug muab DP, yog insoluble nyob rau hauv dej nyob rau hauv tus account ntawm cov cawv siv (tus naj npawb ntawm C atoms nyob rau hauv lub alkyl chian≥16) yog dealt nrog nyias.

Nyob rau hauv cov xwm txheej ntawm alkyl polyglucoside synthesis catalyzed los ntawm cov kua qaub, lwm yam khoom xws li polyglucose ether thiab xim impurities yog generated.Polyglucose yog ib qho amorphous khoom tsim los ntawm glycosyl polymerization thaum lub sij hawm synthesis txheej txheem.Cov hom thiab concentration ntawm cov tshuaj tiv thaiv theem nrab nyob ntawm cov txheej txheem tsis, xws li kub, siab, cov tshuaj tiv thaiv, thiab lwm yam. alkyl polyglycosides ntau lawm nyob rau hauv xyoo tas los no yog kom txo qis kev tsim cov khoom lag luam theem nrab ntsig txog kev sib txuas.

Feem ntau, luv-chain cawv-raws li (C8/10-OH) thiab qis DP (loj cawv ntau dhau) alkyl glycosides muaj teeb meem tsawg tshaj plaws. Nyob rau hauv cov tshuaj tiv thaiv theem, nrog rau kev nce ntawm cov cawv ntau dhau, cov khoom lag luam theem nrab txo qis. Nws txo cov thermal stress thiab tshem tawm cov cawv ntau dhau thaum tsim cov khoom pyrolysis.

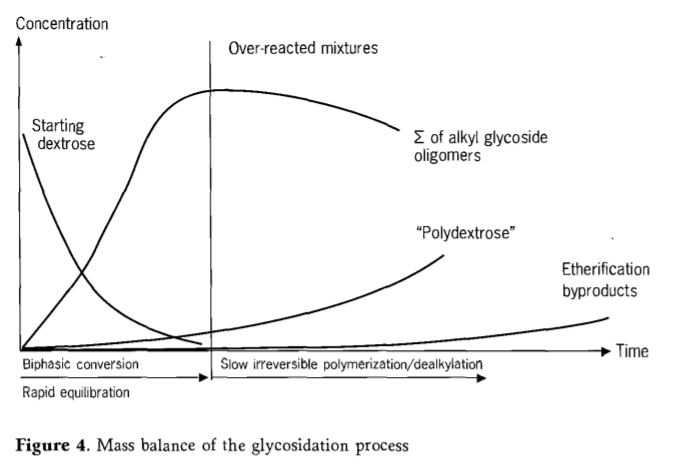

Fisher glycosidation tuaj yeem piav qhia raws li tus txheej txheem uas cov piam thaj reacts sai heev hauv thawj kauj ruam thiab oligomer equilibrium tiav.Cov kauj ruam no yog ua raws li qeeb degradation ntawm alkyl glycosides.Cov txheej txheem degradation muaj cov kauj ruam xws li dealkylation thiab polymerization, uas, ntawm kev nce concentrations, irreversibly zoo dua cov tshuaj tiv thaiv thermolucose. Cov tshuaj tiv thaiv lub sij hawm hu ua overreaction.Yog tias cov tshuaj tiv thaiv raug txiav ntxov ntxov, cov tshuaj tiv thaiv sib xyaw ua ke muaj cov piam thaj ntau ntxiv.

Kev poob ntawm cov tshuaj nquag ntawm alkyl glucoside hauv cov tshuaj tiv thaiv sib xyaw muaj kev sib raug zoo nrog kev tsim ntawm polyglucose. Nyob rau hauv cov ntaub ntawv ntawm cov tshuaj tiv thaiv ntau dhau, cov tshuaj tiv thaiv sib tov maj mam dhau los ua polyphase dua los ntawm nag lossis daus ntawm polyglucose.Yog li ntawd, cov khoom lag luam zoo thiab cov khoom lag luam tawm los cuam tshuam loj heev los ntawm lub sijhawm ntawm cov tshuaj tiv thaiv kev txiav tawm. Pib nrog cov piam thaj, cov alkyl glycosides hauv cov khoom thib ob yog qis dua hauv cov ntsiab lus, tso cai rau lwm cov polar Cheebtsam (polyglucose) thiab cov khoom seem ntawm cov khoom sib xyaw kom tsis txhob muaj cov carbohydrates rov qab.

Nyob rau hauv cov txheej txheem optimized, cov khoom etherification concentration yog tsawg (nyob ntawm qhov kub thiab txias, lub sij hawm, hom catalyst thiab concentration, thiab lwm yam).

Daim duab 4 qhia txog cov chav kawm ntawm cov tshuaj tiv thaiv ncaj qha ntawm dextrose thiab fatty cawv (C12/14-OH).

Qhov ntsuas kub thiab siab ntawm cov tshuaj tiv thaiv tsis zoo sib xws hauv cov tshuaj tiv thaiv fischer glycation.Yuav kom tsim cov alkyl polyglycosides nrog cov khoom qis qis, siab thiab kub yuav tsum tau yoog rau ib leeg thiab tswj nruj heev.

Alkyl polyglycosides qis hauv cov khoom lag luam thib ob tshwm sim los ntawm cov tshuaj tiv thaiv qis (<100 ℃) hauv acetalization. Txawm li cas los xij, qhov kub tsis tshua muaj tshwm sim rau lub sijhawm cov tshuaj tiv thaiv ntev ntev (nyob ntawm cov saw ntev ntawm cov cawv) thiab cov khoom siv hluav taws xob tsawg tsawg. Cov tshuaj tiv thaiv siab kub (> 100 ℃, feem ntau 110-120 ℃) tuaj yeem ua rau muaj kev hloov pauv hauv cov xim ntawm cov carbohydrates. Los ntawm kev tshem tawm cov tshuaj tiv thaiv qis qis (dej hauv kev sib txuas ncaj qha, cov kab hluav taws xob luv luv hauv cov txheej txheem transacetalization) los ntawm cov tshuaj tiv thaiv sib tov, acetalization equilibrium yog hloov mus rau sab khoom. Yog tias muaj cov dej ntau npaum li cas hauv ib chav tsev ntawm lub sijhawm, piv txwv li los ntawm cov tshuaj tiv thaiv kub siab, yuav tsum tau muab rau kev tshem tawm cov dej no los ntawm cov tshuaj tiv thaiv sib tov. Qhov no txo qis cov tshuaj tiv thaiv theem nrab (tshwj xeeb tshaj yog qhov tsim ntawm polydextrose) uas tshwm sim hauv dej. Lub evaporation efficiency ntawm cov tshuaj tiv thaiv theem tsis yog nyob ntawm qhov siab xwb, tab sis kuj evaporation cheeb tsam, thiab lwm yam. Cov tshuaj tiv thaiv ib txwm muaj nyob rau hauv transacetalization thiab ncaj qha synthesis variants yog nyob nruab nrab ntawm 20 thiab 100mbar.

Lwm qhov tseem ceeb ntawm kev ua kom zoo dua qub yog kev txhim kho cov kev xaiv catalysts nyob rau hauv cov txheej txheem glycosidation, yog li inhibiting, piv txwv li, polyglucose tsim thiab etherification.Raws li twb tau hais lawm, acetal los yog thim rov qab acetal hauv Fischer synthesis yog catalyzed los ntawm acids.Raws li txoj cai, ib qho kua qaub ntawm lub zog txaus yog tsim rau lub hom phiaj no, xws li sulfuricene acid thiab sulfuric acid. succinic acid.Cov tshuaj tiv thaiv yog nyob ntawm acidity thiab cov concentration ntawm cov kua qaub hauv cawv. Cov tshuaj tiv thaiv thib ob uas tuaj yeem ua rau cov kua qaub (piv txwv li, polyglucose tsim) tshwm sim feem ntau nyob rau hauv lub polar theem (kab dej) ntawm cov tshuaj tiv thaiv sib tov, thiab alkyl chains uas tuaj yeem txo qis los ntawm kev siv cov hydrophobic acids tsawg (xws li benprimares alkylfonic acid) yaj. theem ntawm cov tshuaj tiv thaiv sib tov.

Tom qab cov tshuaj tiv thaiv, cov kua qaub catalyst yog neutralized nrog lub hauv paus tsim nyog, xws li sodium hydroxide thiab magnesium oxide.Cov tshuaj tiv thaiv neutralized yog cov tshuaj daj daj daj uas muaj 50 mus rau 80 feem pua cov roj cawv. Cov dej cawv muaj roj ntau yog vim qhov sib piv molar ntawm carbohydrates rau fatty alcohols. Qhov piv txwv no tau hloov kho kom tau txais DP tshwj xeeb rau kev lag luam alkyl polyglycosides, thiab feem ntau yog nyob nruab nrab ntawm 1: 2 thiab 1: 6.

Cov dej cawv ntau dhau raug tshem tawm los ntawm lub tshuab nqus tsev distillation. Cov xwm txheej tseem ceeb ntawm ciam teb suav nrog:

- Cov ntsiab lus ntawm cov dej cawv seem hauv cov khoom yuav tsum yog<1% vim lwm yam

ntse solubility thiab tsw yog adversely cuam tshuam.

- Txhawm rau txo qis kev tsim cov khoom lag luam pyrolysis tsis xav tau lossis cov khoom tsis zoo, thermal stressing thiab lub sijhawm nyob ntawm cov khoom lag luam yuav tsum tau khaws cia kom tsawg li sai tau hauv kev vam khom rau cov saw ntev ntawm cov cawv.

- Tsis muaj monoglycoside yuav tsum nkag mus rau hauv distillate vim hais tias cov distillate yog rov ua dua nyob rau hauv cov tshuaj tiv thaiv li ntshiab fatty cawv.

Nyob rau hauv cov ntaub ntawv ntawm dodecanol / tetradecanol, cov kev cai no yog siv rau kev tshem tawm cov rog rog ntau, uas yog txaus siab los ntawm multistage ditillation. Nws yog ib qho tseem ceeb kom nco ntsoov tias raws li cov ntsiab lus ntawm fatty alcohols txo, lub viscosity nce ntau. Qhov no obviously impairs tshav kub thiab huab hwm coj hloov nyob rau hauv lub kawg distillation theem.

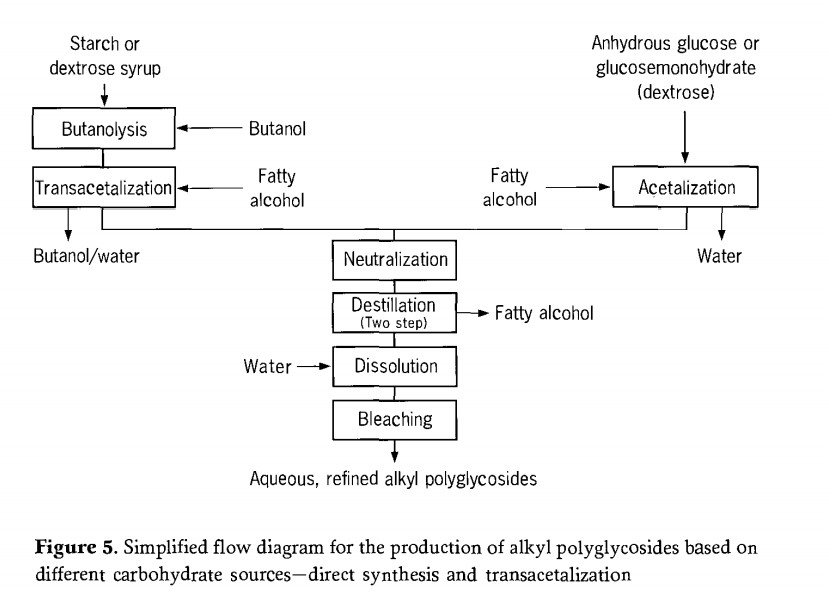

Yog li ntawd, nyias los yog luv-ntau evaporators nyiam dua. Nyob rau hauv cov evaporators, cov neeg kho tshuab txav zaj duab xis muab siab dua evaporation efficiency thiab luv luv cov khoom nyob rau hauv lub sij hawm, raws li zoo raws li lub nqus tsev vacuum. Cov khoom kawg tom qab distillation yog yuav luag dawb huv alkyl polyglycoside, uas accumulates raws li ib tug khoom nrog ib tug melting point ntawm 70 ℃ to 150 ℃. Cov txheej txheem tseem ceeb ntawm alkyl synthesis yog sau tseg raws li daim duab 5.

Nyob ntawm cov txheej txheem tsim khoom siv, ib lossis ob lub voj voog dej cawv ntws los ntawm kev tsim cov alkyl polyglycoside; Cov dej cawv ntau dhau, qhov uas cov cawv cawv luv luv tuaj yeem yuav luag zoo tag nrho. Cov cawv no tuaj yeem rov siv dua hauv cov tshuaj tiv thaiv tom ntej. Qhov yuav tsum tau ua kom huv los yog qhov zaus uas yuav tsum tau ua kom huv huv yog nyob ntawm cov impurities hauv cov cawv. Qhov no feem ntau nyob ntawm qhov zoo ntawm cov txheej txheem ua ntej (piv txwv li cov tshuaj tiv thaiv, tshem tawm cawv).

Tom qab tshem tawm cov rog rog, cov tshuaj alkyl polyglycoside nquag yaj ncaj qha hauv dej kom cov kua nplaum 50 mus rau 70% alkyl polyglycoside muab tshuaj. Nyob rau hauv cov kauj ruam tom ntej refining, qhov muab tshuaj txhuam no tau ua haujlwm rau hauv cov khoom ntawm kev txaus siab zoo raws li cov kev xav tau ntawm kev ua haujlwm. Cov kauj ruam ua kom zoo no tuaj yeem suav nrog cov tshuaj dawb ntawm cov khoom, kev hloov kho cov yam ntxwv ntawm cov khoom lag luam, xws li Ph tus nqi thiab cov ntsiab lus ntawm cov tshuaj nquag, thiab microbial stabilization. Nyob rau hauv cov ntaub ntawv patent, muaj ntau yam piv txwv ntawm reductive thiab oxidative bleaching thiab ob-theem txheej txheem ntawm oxidative bleaching thiab reductive stabilization. Kev siv zog thiab yog li tus nqi koom nrog hauv cov txheej txheem no kom tau txais qee yam zoo, xws li xim, nyob ntawm qhov kev xav tau ntawm kev ua haujlwm, ntawm cov khoom pib, DP xav tau thiab qhov zoo ntawm cov txheej txheem txheej txheem.

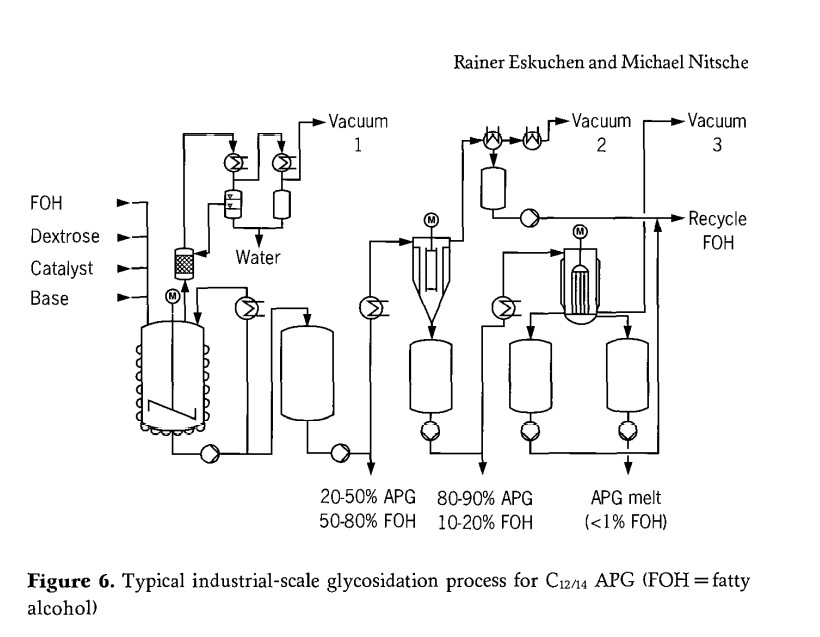

Daim duab 6 qhia txog cov txheej txheem tsim khoom lag luam rau cov saw ntev alkyl polyglycosides (C12/14 APG) los ntawm kev sib txuas ncaj qha)

Post lub sij hawm: Oct-13-2020